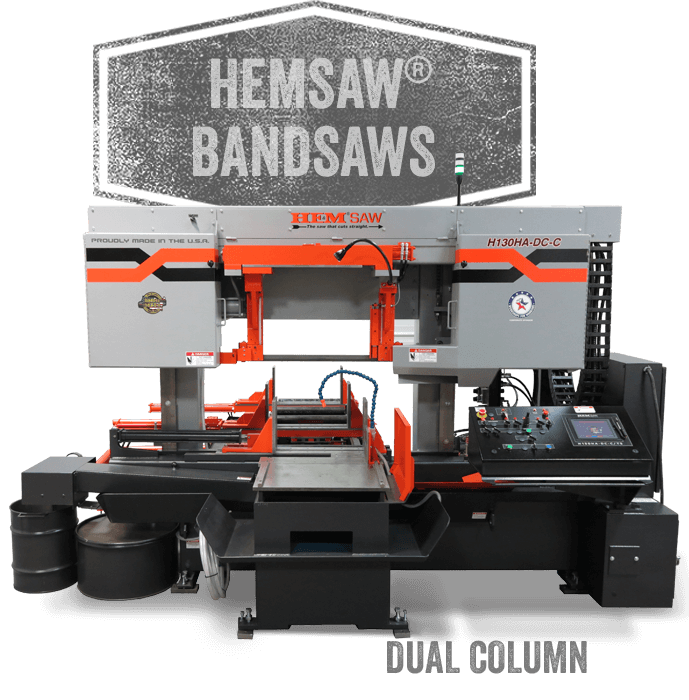

Band Saw Blades For Metal

6 Inch Band Saws

Just like with thicker veneer, you cut the laminates one at a time from a thick wood piece.

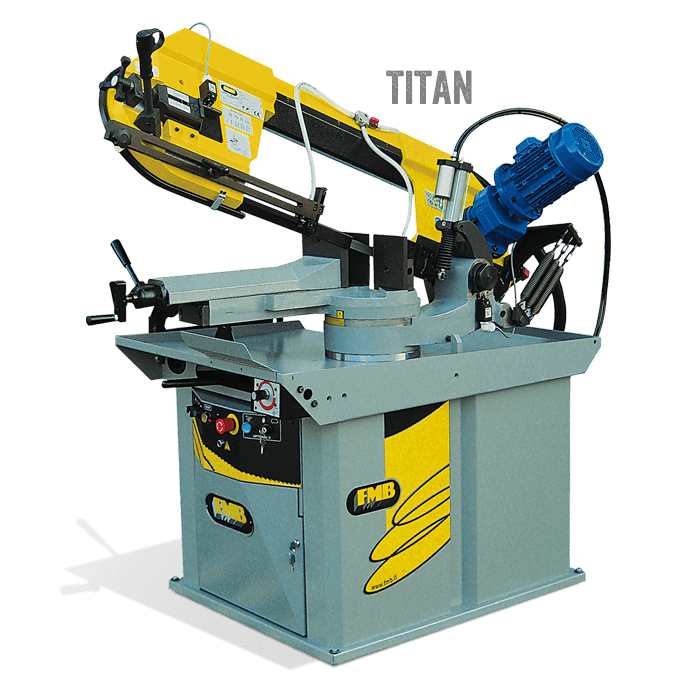

Another heavy-duty machine that can do professional work. It includes a built-in lamp for halogen work.